Firmware

So now that I had assembled the hardware, it was firmware time. I wanted to send an address:direction:speed string (eg "A001:F:S3") over the serial connection to the Arduino, and have the Arduino build the corresponding DCC packet and drive the H-Bridge accordingly.The Arduino firmware I wrote to implement the DCC spec is interesting from two respects: it uses timer interrupts and it writes to the microcontroller ports directly. But I'm getting ahead of myself a little...

DCC Specification

Before going any further, we'd probably need to have a look at the DCC spec. DCC sends 1's and 0's as square waves of different lengths. A short square wave (58us * 2) represents a 1, and a longer one (>95us * 2) is a 0.

Before going any further, we'd probably need to have a look at the DCC spec. DCC sends 1's and 0's as square waves of different lengths. A short square wave (58us * 2) represents a 1, and a longer one (>95us * 2) is a 0.

These 1's and 0's are then collected into packets and transmitted on to the rails. Each packet contains (at least):

- A preamble of eleven 1's

- An address octet. This is the address of the train you want to control on the layout.

- A command octet. This is 1 bit for direction and 7 bits for speed.

- An error checking octet. This is the address octet XORed with the command octet

If a train picks up a control packet that is not addresses to it, the command is ignored - the train keeps doing what it was last instructed to do, all the while still taking power from the rails. When nothing has to be changed, power must still be supplied to the trains so packets are still broadcast on the rails to supply power. In this case either the previous commands can be repeated or idle packets sent.

Driving the H-Bridge

First, I had to figure out a way of driving the H-Bridge signals. Driving both legs of the H-Bridge incorrectly won't short out the power supply, but it will give ugly transitions on the rails ( instead of

instead of  ) and DCC decoders may not be able to decode the packet. The H-Bridge control signals should be driven differentially - both must change at the same time. This ruled out using

) and DCC decoders may not be able to decode the packet. The H-Bridge control signals should be driven differentially - both must change at the same time. This ruled out using digital_write() to set pin states for two reasons: it can only change one pin at a time; and it's too slow.

So I needed to directly manipulate the a microcontroller digital port. I chose pins 11 and 12 which are both in PORTB. By directly manipulating PORTB with a macro, I could now change the pins at the same instant in time.

#include <avr/io.h> #define DRIVE_1() PORTB = B00010000#define DRIVE_0() PORTB = B00001000

When to use these macros was the next problem.

Timing

As the DCC spec specifies quite a tight timing requirement on the 1 and 0 waveforms, I decided I should use the timer on the Arduino's microcontroller. Using the timer, I could place the transitions on the outputs accurately. So I set up the timer so that the interrupt would trigger every 58us. To simplify things, I defined the time of a 0 bit to be twice that of the 1 bit, ie 116us between transitions. For example, if I wanted to send a1, I would drive LO HI, and I'd drive LO LO HI HI to transmit a 0. The timer setup routine is shown below.

void configure_for_dcc_timing() {

/* DCC timing requires that the data toggles every 58us

for a '1'. So, we set up timer2 to fire an interrupt every

58us, and we'll change the output in the interrupt service

routine.

Prescaler: set to divide-by-8 (B'010)

Compare target: 58us / ( 1 / ( 16MHz/8) ) = 116

*/

// Set prescaler to div-by-8

bitClear(TCCR2B, CS22);

bitSet(TCCR2B, CS21);

bitClear(TCCR2B, CS20);

// Set counter target

OCR2A = timer2_target;

// Enable Timer2 interrupt

bitSet(TIMSK2, OCIE2A);

}

The interrupt service routine (ISR) for the timer is shown below. For accurate timing when using a count target for a timer, I have to reset the timer counter straight away. Straight after, I figure out which level I need to drive and drive it. The point is, there's a fixed amount of processor cycles needed from when the ISR fires until I drive the pins. After this, I can be a little more relaxed about anything else I need to do during the ISR, like update the pattern count or load a new frame (explained later).

#include <avr/interrupt.h>

...

ISR( TIMER2_COMPA_vect ){

TCNT2 = 0; // Reset Timer2 counter to divide...

boolean bit_ = bitRead(dcc_bit_pattern_buffered[c_buf>>3], c_buf & 7 );

if( bit_ ) {

DRIVE_1();

} else {

DRIVE_0();

}

/* Now update our position */

if(c_buf == dcc_bit_count_target_buffered){

c_buf = 0;

load_new_frame();

} else {

c_buf++;

}

};Building Control Packets

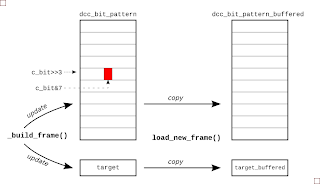

There are two steps to getting packet UI data ready for transmission. First, the UI pattern must be constructed using the latest address, speed and direction data that the firmware has received from the serial link. And then when the driver interrupt is ready for it, the packet is copied to a buffer area so that output data is never updated mid way through the transmission of a packet. The picture right gives the general idea.

There are two steps to getting packet UI data ready for transmission. First, the UI pattern must be constructed using the latest address, speed and direction data that the firmware has received from the serial link. And then when the driver interrupt is ready for it, the packet is copied to a buffer area so that output data is never updated mid way through the transmission of a packet. The picture right gives the general idea.

To keep things simple for the interrupt routine, I built a list of highs and lows that must be transmitted for a given packet. Now, each time the ISR fires it just outputs the next level in the list. For example, if I wanted to drive a packet of

1001, I'd actually be driving 12 UIs (LO HI, LO LO HI HI, LO LO HI HI, LO HI) on the pins. So I set up an array of bytes called dcc_bit_pattern to hold this HI LO HI ... sequence. It was sized so that it would hold the worst case packet length, transmitting all 0's.

So after receiving a new direction instruction, I'd determine the frame data and write it to this packet buffer in UI format. All the while, I'd be keeping a count of the number of UIs in the packet, and when I'd finished building the packet, squirrel this final UI count away for use later. To build a packet from the address, speed and direction data, I call

build_packet(), which in turn calls a general-purpose packet builder function called _build_packet(), shown next:

void _build_frame( byte byte1, byte byte2, byte byte3) {

// Build up the bit pattern for the DCC frame

c_bit = 0;

preamble_pattern();

bit_pattern(LOW);

byte_pattern(byte1); /* Address */

bit_pattern(LOW);

byte_pattern(byte2); /* Speed and direction */

bit_pattern(LOW);

byte_pattern(byte3); /* Checksum */

bit_pattern(HIGH);

dcc_bit_count_target = c_bit;

};

The byte_pattern() function takes a byte and converts it to a string of UIs. For example, given an address of 12, this is b0000_1010 in binary and the byte_pattern() function would add the UIs {LO LO HI HI, LO LO HI HI, LO LO HI HI, LO LO HI HI, LO HI, LO LO HI HI, LO HI, LO LO HI HI} to the current packet being constructed.

The function

byte_pattern() uses bit_pattern() which really does all the donkey work, doing the actual logic-to-UI conversion. Starting at position held in variable c_bit, bit_pattern() will lay down LO HI or LO LO HI HI for each bit and will increment the UI counter c_bit as it goes.

void bit_pattern(byte mybit){

bitClear(dcc_bit_pattern[c_bit>>3], c_bit & 7 );

c_bit++;

if( mybit == 0 ) {

bitClear(dcc_bit_pattern[c_bit>>3], c_bit & 7 );

c_bit++;

}

bitSet(dcc_bit_pattern[c_bit>>3], c_bit & 7 );

c_bit++;

if( mybit == 0 ) {

bitSet(dcc_bit_pattern[c_bit>>3], c_bit & 7 );

c_bit++;

}

}

The position of a given UI in the packet's byte array dcc_bit_pattern is decoded from the UI counter. The three LSBs, c_bit[2:0] are the position within the byte and the remaining MSBs are the byte address. This explains the bitClear(dcc_bit_pattern[c_bit>>3], c_bit & 7 ) stuff that's going on both here and in the ISR.

When the packet is built and the driver interrupt is ready for it, the packet is copied to a buffer area so that a transmitted packet is never updated mid way through being updated. The function

load_new_packet() takes care of copying the new UI data and updating the buffered UI target count.

Reading Control Strings via Serial I/O

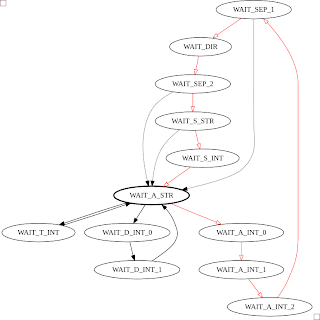

To read a control string from the serial port, I've used the

To read a control string from the serial port, I've used the Serial module and a finite state machine (FSM). The FSM detects a string in the form: "A" digit digit digit ":" "F" or "B" ":" "S" digit. If there's a handier way to do this, I'm all ears. The FSM diagram for this is shown below, with the red transitions being the main loop, and the dashed transistions being followed when there's an error. I snuck a few testmodes in there too: one so I could drive the rails constantly long enough to put a multimeter on them; and another to tweak the timer target count

Having the firware controlled by strings passed through the serial port opens up some interesting capabilities. For instance, I didn't know the address of the train initially, so I wrote small Python script to cycle through all the addresses and wait a while to see if the train responded (it turned out to be '1'):

#! /usr/bin/env python

""" Try to find the address of dad's train... """

from time import sleep

import serial

link = serial.Serial('/dev/ttyUSB0', baudrate=9600, timeout=2)

def search_address():

for address in range(127):

print "Address %03d" % (address)

link.write("A%03d:F:S3" % address )

sleep(10)

if __name__ == '__main__':

search_address()

I also wrote one to move the train back and forth along the track:#! /usr/bin/env python

from time import sleep

import serial

link = serial.Serial('/dev/ttyUSB0', baudrate=9600, timeout=2)

print "Link:", link

for i in xrange(10):

link.write("A001:F:S5")

sleep(10)

link.write("A001:B:S6")

sleep(14)

The Grand Opening

So after all this, you might be interested in what my dad thought of the whole endeavour. I took it back home and showed him, and he was like "Meh, that's nice I suppose. I'm more interested in the wireless control that's about these days...". Fair play, no point in using old tech, I suppose!References

- teh codez: [github]

- Arduino Port Mapping: [arduino.cc]

- Port Manipulation: [arduino.cc]

- Benchmarking different ways of changing Arduino pins: [billporter.info]

11 comments:

Hi

I'm not having much luck, the project looked so great I went out and bought all the kit. I soldered the components together, loaded the firmware, started python all this seems to work but I cannot get my dcc train to move?

I know that the DCC train is on address 3, I send the command and I can see the signal go to the ardunio from the on board LED.

If I put a normal DC train on the track it moves...

If I unplug pin 11 & 12 the DC train stops...

Any ideas what the issue could be?

@GFletch

I'm sorry to hear things are not totally working out for ye! Sounds like you're nearly there though.

I'd guess that since a DC train is moving, you're not getting a DCC voltage pattern on the rails.

Do you have a multimeter? There are a few things you could check. First thing would be to check out your driver cct.

Unplug pins 11 & 12, and instead put one wire in 5V and the other in 0V (gnd) on the arduino. We're forcing the bridge to drive one way so measure the voltage between the rails. You should see half of your high supply voltage. In my case it would be +6V.

Now swap over the wires, the one that was in 5V goes to 0V, and the one that was in 0V goes to 5V. If you measure the voltage across the rails, you should see negative half your high supply voltage.

Or, if you seen -6V (say) first, you should see +6V when you swap the wires.

If you are seeing these voltages, we can probably rule out your cct, If not, post high-res pictures of the top and bottom sides of your board so I can have a look.

Which arduino board are you using?

Hi Marty

thanks for coming back to me, I've come back to look at this project again and I just cant get it working :(

I'm sure its something stupid I'm doing wrong.

I made a quick video of what I am trying.

I am running the system off of 5v at the moment and have hooked up a DCC decoder that shows me the binary packet data sent over the rails, this is what I am using to test.

When I remove the lines of code around // messing I get more info back from the command line, I guess this is a test? That said I can only send 2 commands and then it doesnt print any results back.

Perhaps you can give me some pointers?

Here's my set up...

http://youtu.be/getXvaPLrO0

Thanks

Gary

Marty,

Very cool stuff. I'm just learning about the great realm of Arduinos and everything about. (it is amazing how excited one get when they learn how to change the way an LED flashes, I'm an architect by trade so I have no EEE or programming experience)

What I'm hoping to learn is how to use an Arduino as the brains to a turnout control panel. IE press a button on the panel and have the arduino then send out DCC commands over my LocoNet bus to change multiple turnout decoder position for Routing.

What you have here is very interesting, still way above my head but cool all the same.

Jason

@GFletch: Did you make any progress on your setup?

It's a bit difficult to debug things from a distance, so I'm not sure that I'll be much help. Have you a multimeter? Have you done a few spot-checks of voltages in the circuit?

Hi,

I tried this solution on a different microcontroller (Teensy) and it started to work after some minor modifications. However, the moment I found proper train address it worked for several seconds and then I smelled burned plastic - breadboard started to heat at legs 4/5/12/13 on L293D. I wonder if making connections permanent will be better? L293D also was very hot.

@Sergei - glad you got it working, but sad about your breadboard :(

Creating that circuit permanently on stripboard or something is definitely a good idea. Those pins you mentioned are usually soldered to big pads of metal to draw the heat away from the chip.

I'll update the blog post with a warning about this. My original cct was on stripboard, not a breadboard so I didn't see that problem. Thanks for pointing it out.

Hi Marty.

With your code and a little customization, i can drive my dcc-onboard loco now. Thanks.

But when I swap the wire or turn around the loco, it can't work. Then I modify the code if( bit_ ) {DRIVE_1();} else {DRIVE_0();} to if( bit_ ) {DRIVE_0();} else {DRIVE_1();}, it works again. So i guess the problem is the polarity of the start of signal. If the start is a +12v it works, but if the start is a -12v it ain't.

Any idea on this?

Hey Marty. This is a great writeup. I have lots of model trains from long ago that have been collecting dust. I would like to get the kids interested while satisfying my inner geek.

I'm marginally familiar with the Arduino Mega 2560, having used it for various purposes around the house. After downloading and studying your code, I have one question that I just can't answer myself: You reference pin10 and have TRIG_ON and TRIG_OFF macros defined for throwing a bit on port B. These are put to work in the ISR, could you tell me how they tie into putting info to the rails? I'd really appreciate it.

Bryan

@Max - That's a weird one! I don't understand what's going on there tbh. Thanks for posting the info, it could come in very handy for someone else.

@Bryan - The TRIG_ stuff isn't important to the operation of the controller, it was a debug feature I added. It's just a small pulse that I put on pin 10 at the start of a data packet transmission so I can trigger my oscilloscope, and tell where the data starts if I'm looking at it.

Thanks for the quick reply Marty. I wasn't quite sure if pin10 was doing something to the driver chip that I wasn't aware of. But thanks for clearing that up. My mind is now at ease and I feel very comfortable buying a new dcc controlled locomotive to test things out ... then I'll upgrade all the old stock to dcc. Until then, I'll be using the Arduino to drive the dc bugs around so the kids can enjoy them ... yeah the kids ...

Post a Comment